Plastic injection molding is the most efficient process for mass production of precision components and stands as a core manufacturing pillar of the QQS Group. As the group’s centralized production hub, the QQS Injection Center possesses integrated capabilities ranging from mold trials and small-batch validation to large-scale mass production. It provides a robust supply chain foundation for our key subsidiaries:

● ATYOU Health Tech: Specializing in disinfection, sterilization, cleaning, and innovative health appliances.

● MIHI Intelligent Tech: Focusing on kitchen cleaning appliances and smart home devices.

● Tracent Precision Tech: Developing MR/AR/AI smart glasses and wearable intelligent equipment.

Through the close collaboration of our internal R&D, mold making, injection molding, PCBA, and assembly teams, we ensure high manufacturing standards from the very early stages of production. This synergy significantly reduces prototype development cycles and maximizes data security for our clients' proprietary designs.

The Injection Center operates not only as an internal support unit but also as an independent contractor, often in synergy with ourMold Manufacturing Center, to serve global clients. Our business scope covers a wide array of industries, including consumer electronics, home appliances, medical supplies, sports equipment, maternal & infant care, personal care, automotive components, agricultural irrigation, and sanitary products.

We possess extensive field experience and strict quality control standards, particularly in niche sectors such as cleaning appliances, sterilization equipment, smart products, and precision consumer electronics. Leveraging the Group’s integrated resource system, the center ensures efficient synergy from design to production, delivering stable and reliable injection molding and component manufacturing solutions for international partners.

Following a major automation upgrade in 2021, the center continued to introduce multi-color, high-speed, and all-electric injection molding machines, forming a modern and highly efficient production system.

Core Equipment Portfolio: Precision Injection Equipment: Featuring high-speed all-electric machines from TOSHIBA and JSW (Japan), parallel twin-color machines from FCS (Taiwan), and multiple high-tonnage units from WELLTEC and Yizumi (up to 750T). Auxiliary Processing: Equipped with ultrasonic welding machines, laser marking systems (SMART UV3), hot stamping machines, and multi-zone mold temperature controllers. Materials & Processes: Capable of high-quality molding for materials such as PE, PP, PC, PETG, ABS, and SAN, integrated with secondary finishing services like painting, laser engraving, and hot stamping. |

QQS Group Injection Molding Workshop |

Dedicated to producing high-standard components, the QQS injection team has mastered a broad spectrum of engineering-driven molding technologies to solve complex manufacturing challenges. Our core capabilities include:

● High-Precision Molding

● Overmolding & Insert Molding

● Two-Shot (Double Injection) Molding

● Hot Runner & Multi-Cavity Systems

● Rapid Tooling & Process Optimization

● Moldflow Simulation & Manufacturability Verification

Through full-process digital management, the center achieves traceable production and real-time parameter monitoring, ensuring consistent product quality and process stability.

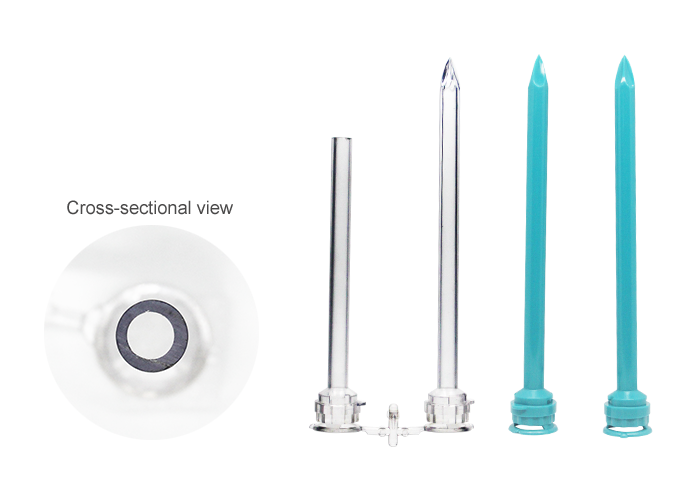

Injection Molding Precision Medical Accessories |

Injection Molding/OEM manufacturing Large-scale Beauty Equipment |

Injection Molding Mini Projector Parts |

Injection Molding High-end Bathroom Products |

Injection Molding High-end Humidifier Accessories |

Injection Molding Sports Sunglasses |

Adhering to the QQS Group philosophy—"Precision Shapes Quality, Efficiency Builds Trust"—the Injection Center implements a rigorous quality control system and project management workflow. We ensure that every product meets international standards in terms of precision, cycle time, and reliability.

With continuous investment in intelligent inspection systems and systematic management, the center maintains an optimal balance between manufacturing efficiency and product excellence, providing long-term, dependable production support for both the Group and its global partners.